-

Stainless Steel Sheet Metal Fabrication

-

Aluminium Sheet Metal Fabrication

-

Precision Sheet Metal Fabrication

-

Sheet Metal Cabinet Fabrication

-

Sheet Metal Enclosure

-

Sheet Metal Box Fabrication

-

Precision Metal Stamping

-

Laser Cut Sheet Metal Service

-

Sheet Metal Bending

-

Sheet Metal Welding

-

Mild Steel Fabrication

-

Sheet Metal Bracket

Aluminum Bending Welding Service Sheet Metal Fabrication Service

| Place of Origin | Suzhou, China |

|---|---|

| Brand Name | JDC |

| Certification | ISO 9001 : 2015 |

| Model Number | JDC087 |

| Minimum Order Quantity | 25 |

| Price | USD $1~$100/piece |

| Packaging Details | 30cm*30cm*50cm; According to the customer's requirements |

| Delivery Time | 10~30 days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 10000 pieces per month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Aluminum Bending Welding Service Sheet Metal Fabrication Service | Material | Mild Steel; Stainless Steel; Aluminum... |

|---|---|---|---|

| Color | Black; White; Silver... | Process Method | Laser Cutting; Bending; Welding; Stamping... |

| Surface | Powder Coating; Anodizing; Sand Blasting; Brushed Finishing... | Size | Custom |

| Package | Carton; Wooden Case... | Application | Industry,Metal Parts,home Appliance,Auto /medical/agricultural/train/valve/textile,Ductwork |

| Type | OEM Parts,Stamping Hardware Part,sheet Metal | Tolerance | 0.003~0.01mm,Customized |

| Thickness | 0.5mm-20mm,Various | ||

| High Light | Cnc Aerospace Sheet Metal Fabrication,Aerospace Sheet Metal Fabrication Companies,JDC Cnc Sheet Metal Fabrication |

||

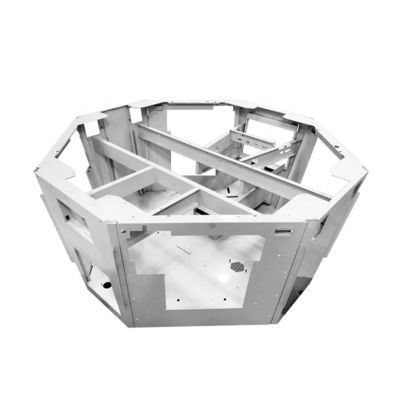

Aluminum Bending Welding Service Sheet Metal Fabrication Service

Description

1. Aluminum Bending Welding Service: Our Aluminum Bending Welding Service focuses on bending and welding aluminum sheet metal to create custom components and structures. This service is an integral part of our overall Sheet Metal Fabrication Service, which encompasses a wide range of processes related to shaping and manipulating sheet metal.

2. Comprehensive Sheet Metal Fabrication Service: Our Sheet Metal Fabrication Service is a comprehensive solution that covers various aspects of working with sheet metal. It includes cutting, bending, welding, and other fabrication techniques to transform raw sheet metal into finished products. By offering a complete range of services, we provide our clients with a convenient and efficient solution for their sheet metal needs.

3. Aluminum Bending: Within our Sheet Metal Fabrication Service, we specialize in bending aluminum sheets to achieve desired shapes, angles, and dimensions. Whether it's simple bends or complex configurations, our skilled technicians use advanced bending equipment to ensure accurate and precise results.

4. Aluminum Welding: Another important aspect of our Sheet Metal Fabrication Service is aluminum welding. We have experienced welders who are proficient in joining aluminum components using various welding techniques. This enables us to create strong and durable structures or assemble multiple sheet metal pieces into a unified product.

5. Integration of Aluminum Bending Welding into Sheet Metal Fabrication Service: By offering Aluminum Bending Welding Service as part of our broader Sheet Metal Fabrication Service, we provide clients with a one-stop solution for their aluminum fabrication needs. They can benefit from our expertise in both bending and welding, ensuring seamless integration of these processes within their project.

Through our Aluminum Bending Welding Service as part of the Sheet Metal Fabrication Service, clients can access specialized expertise in working with aluminum sheet metal. Our comprehensive range of services allows us to handle projects from start to finish, delivering high-quality fabricated components that meet their precise requirements.

Surface Treatment

Main Technical specifications

Picture

![]()

Application

1. Architectural and Construction: Our Sheet Metal Fabrication Service, including Aluminum Bending Welding, is commonly utilized in architectural and construction projects. It involves fabricating customized metal components, such as decorative panels, wall claddings, roofing elements, and structural supports.

2. Electronics and Technology: The Sheet Metal Fabrication Service, including Aluminum Bending Welding, is extensively employed in the electronics and technology sectors. It encompasses the production of electronic enclosures, chassis, brackets, and mounting racks that protect and support sensitive electronic components.

3. Industrial Equipment and Machinery: The Sheet Metal Fabrication Service, incorporating Aluminum Bending Welding, is crucial in the manufacturing of industrial equipment and machinery. It includes the fabrication of control panels, cabinets, frames, and machine guards that provide structural integrity and protection for equipment.

4. Automotive and Transportation: Our Sheet Metal Fabrication Service, featuring Aluminum Bending Welding, is widely applied in the automotive and transportation industries. It involves the manufacturing of vehicle components, such as body panels, brackets, supports, and structural reinforcements, ensuring strength and durability.

5. Renewable Energy: The Sheet Metal Fabrication Service, including Aluminum Bending Welding, plays a vital role in the renewable energy sector. It encompasses the fabrication of enclosures, mounting systems, and frames for solar panels, wind turbines, and energy storage systems.

In summary, our Aluminum Bending Welding Service, as part of the Sheet Metal Fabrication Service, finds diverse applications in architectural and construction projects, electronics and technology, industrial equipment and machinery, automotive and transportation, as well as renewable energy sectors. The comprehensive nature of our Sheet Metal Fabrication Service allows us to cater to the unique requirements of each industry, delivering high-quality fabricated components that contribute to the success of various applications.