-

Stainless Steel Sheet Metal Fabrication

-

Aluminium Sheet Metal Fabrication

-

Precision Sheet Metal Fabrication

-

Sheet Metal Cabinet Fabrication

-

Sheet Metal Enclosure

-

Sheet Metal Box Fabrication

-

Precision Metal Stamping

-

Laser Cut Sheet Metal Service

-

Sheet Metal Bending

-

Sheet Metal Welding

-

Mild Steel Fabrication

-

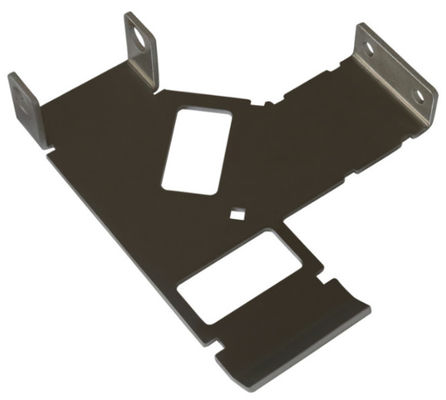

Sheet Metal Bracket

Precision Sheet Metal Fabrication Sheet Metal Manufacturing

| Place of Origin | Suzhou, China |

|---|---|

| Brand Name | JDC |

| Certification | ISO 9001 : 2015 |

| Model Number | JDC004 |

| Minimum Order Quantity | 20 |

| Price | USD $0.2~$100/piece |

| Packaging Details | 30cm*30cm*30cm; According to the customer's requirements |

| Delivery Time | 10~30 days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 20000 pieces per month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Precision Sheet Metal Fabrication Sheet Metal Manufacturing | Material | Aluminum, Steel, SPCC, SGCC, SECC |

|---|---|---|---|

| Process Method | Laser Cutting; Bending; Welding; Stamping... | Size | Customed Size |

| Application | Industrial,building Material,Auto,all Fields,Machine Parts | Surface Finish | Automotive Industry; Appliance Parts; Mechanical Industry; Electronic Industry; IT Industry |

| Tolerance | ±0.03mm,0.1-0.5mm,+ - 0.1mm,+/-0.1~0.05mm,ST6 | Color | Customized Color,Customzied Aluminum Alloys,Bright,White,Any Color |

| Thickness | 1mm~8mm,0.5mm-8mm,1.0mm-3.0mm | Surface Treatment | Powder Coating; Sandblasting |

| High Light | SUS316 Precision Sheet Metal Stamping Parts,Precision Sheet Metal Stamping Parts 3.0mm,Precision Machining Sheet Metal JDC |

||

Precision Sheet Metal Fabrication Sheet Metal Manufacturing

Description

Precision Sheet Metal Fabrication is a specialized manufacturing process that involves the precise shaping, cutting, and manipulation of sheet metal to create a variety of components and products. Sheet Metal Manufacturing, as a key aspect of this process, plays a crucial role in transforming flat sheets of metal into functional and customized parts. Here is a description focusing on Sheet Metal Manufacturing:

Sheet Metal Manufacturing is the core foundation of Precision Sheet Metal Fabrication. It encompasses a range of techniques and processes used to transform raw sheet metal into finished products with exceptional precision and accuracy. Through the use of specialized machinery, such as shears, presses, and CNC equipment, the sheet metal is carefully cut, formed, bent, and assembled to create a wide range of components.

In Sheet Metal Manufacturing, flat sheets of various metals, such as steel, aluminum, or stainless steel, are carefully selected based on their properties and desired application. The sheets are then processed using techniques like shearing, punching, and laser cutting to achieve precise dimensions and shapes.

The formed and cut sheet metal pieces are then subjected to various manufacturing processes such as bending, folding, and welding, to create complex structures and components. Sheet Metal Manufacturing also involves techniques like riveting, fastening, and spot welding to join multiple parts together securely.

With the advancement of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies, Sheet Metal Manufacturing has become highly efficient and accurate. CNC machines precisely follow digital design specifications, ensuring consistent quality and minimizing human error.

Sheet Metal Manufacturing finds applications in numerous industries, including automotive, aerospace, electronics, and architecture. It is used to fabricate components such as chassis, enclosures, brackets, panels, and frames. The versatility and cost-effectiveness of Sheet Metal Manufacturing make it a preferred choice for producing high-quality, durable, and customized parts.

In summary, Sheet Metal Manufacturing is a fundamental process within Precision Sheet Metal Fabrication that involves cutting, forming, bending, and assembling flat sheets of metal to create precise and functional components for various industries. Through the utilization of advanced machinery and techniques, Sheet Metal Manufacturing enables the production of high-quality and customized sheet metal products.

What we can do?

Main Technical specifications

Picture

![]()

Application

Sheet Metal Manufacturing, as a vital component of Precision Sheet Metal Fabrication, finds diverse applications across various industries. Here are five examples highlighting the applications of Sheet Metal Manufacturing:

1. Automotive Industry: Sheet Metal Manufacturing plays a crucial role in the automotive sector. It is utilized in the production of automotive body panels, chassis components, engine enclosures, brackets, and structural parts. The precise fabrication and assembly of sheet metal parts ensure structural integrity, safety, and aesthetic appeal in vehicles.

2. Electronics and Telecommunications: The electronics industry extensively relies on Sheet Metal Manufacturing for the production of enclosures, racks, cabinets, and heat sinks for electronic devices such as computers, servers, telecommunications equipment, and consumer electronics.

3. Sheet metal's durability, electromagnetic shielding properties, and thermal management capabilities make it suitable for these applications.

4. Aerospace and Aviation: Sheet Metal Manufacturing is indispensable in the aerospace industry, where lightweight yet robust components are essential. It is used to fabricate aircraft structures, engine components, wings, fuselage panels, and interior fittings. The precision and strength of sheet metal contribute to the overall performance, safety, and fuel efficiency of aerospace systems.

5. Industrial Equipment: Sheet Metal Manufacturing finds applications in the production of various industrial equipment and machinery. It is used to manufacture enclosures, control panels, machine frames, brackets, and conveyor systems. Sheet metal's durability and versatility make it suitable for demanding industrial environments.

Architecture and Construction: Sheet Metal Manufacturing is employed in architectural and construction projects to create decorative panels, façades, roofs, stairs, railings, and other structural components. The ability to customize sheet metal to specific design requirements allows architects and designers to achieve unique and visually appealing structures.

Sheet Metal Manufacturing plays a vital role in these industries by providing precise, durable, and customized solutions. Its versatility, cost-effectiveness, and wide range of applications make it a preferred choice for fabricating various components and structures.