-

Stainless Steel Sheet Metal Fabrication

-

Aluminium Sheet Metal Fabrication

-

Precision Sheet Metal Fabrication

-

Sheet Metal Cabinet Fabrication

-

Sheet Metal Enclosure

-

Sheet Metal Box Fabrication

-

Precision Metal Stamping

-

Laser Cut Sheet Metal Service

-

Sheet Metal Bending

-

Sheet Metal Welding

-

Mild Steel Fabrication

-

Sheet Metal Bracket

Precision Sheet Metal Fabrication Laser Cutting Bending Parts

| Place of Origin | Suzhou, China |

|---|---|

| Brand Name | JDC |

| Certification | ISO 9001 : 2015 |

| Model Number | JDC008 |

| Minimum Order Quantity | 25 |

| Price | USD $1~$5/piece |

| Packaging Details | According to the customer's requirements |

| Delivery Time | 8~30 days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 10000 pieces per month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Precision Sheet Metal Fabrication Laser Cutting Bending Parts | Size | Customed Size |

|---|---|---|---|

| Color | Customized Color | Material | Carbon Steel, Stainless Steel, Brass, Copper |

| Surface Treatment | Zinc Plating, Brushing | Process | Punching, Bending, Stamping, Deep Drawing |

| Application | Industrial,building Material,Machine Parts | Service | OEM ODM,Sheet Metal Fabrication,OEM/ODM/Customized/Design |

| Packing | Carton,Paper Cases Packing,Wooden Case | Material Thickness | 1.5mm,From 0.2-30mm |

| High Light | Hot Stamping Sheet Metal Precision 1.5mm,Sheet Metal Precision 1.5mm,precision metal additive manufacturing 1.5mm |

||

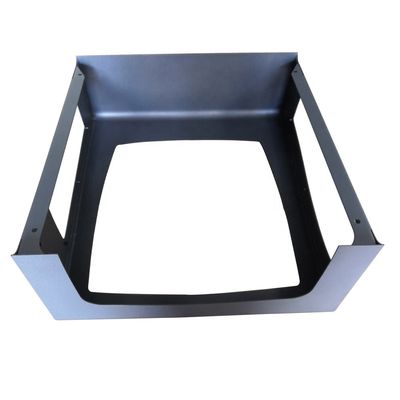

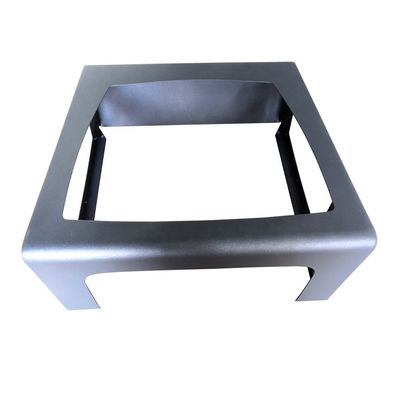

Precision Sheet Metal Fabrication Laser Cutting Bending Parts

Description

Precision Sheet Metal Fabrication involves the fabrication of intricate and accurate sheet metal parts using advanced techniques and equipment. The process starts with laser cutting, which utilizes a high-powered laser beam to precisely cut through the sheet metal with exceptional accuracy and speed. This enables the creation of intricate shapes and precise dimensions.

After laser cutting, the sheet metal parts undergo bending, where they are formed into desired shapes and angles. Precision bending ensures that the components meet the specified tolerances and geometric requirements. This process is achieved using specialized machinery and tooling, resulting in precise and consistent bends.

Precision Sheet Metal Fabrication finds applications in various industries and sectors. It is widely used in the manufacturing of electronic enclosures, chassis, brackets, panels, and other components for electronics and telecommunications equipment. The precise dimensions and high-quality finishes achieved through Precision Sheet Metal Fabrication make it ideal for producing components that require a high level of accuracy and functionality.

In the automotive industry, Precision Sheet Metal Fabrication is employed in manufacturing parts such as brackets, brackets, brackets, and brackets. The precision and durability offered by Precision Sheet Metal Fabrication make it suitable for automotive components that require strict tolerances and reliable performance.

In the aerospace and aviation sectors, Precision Sheet Metal Fabrication is utilized in the production of aircraft components, including structural parts, control panels, and instrument enclosures. The ability to create complex shapes and maintain precise dimensions is crucial for ensuring the safety and performance of aerospace applications.

Precision Sheet Metal Fabrication also plays a significant role in the medical and healthcare industries. It is used in the manufacturing of medical equipment, devices, and cabinets, where accuracy and cleanliness are essential. The high-quality finishes achieved through Precision Sheet Metal Fabrication support the stringent hygiene requirements of the medical field.

Furthermore, Precision Sheet Metal Fabrication is applied in the production of consumer goods, furniture, signage, and architectural elements. Its versatility allows for the creation of aesthetically pleasing designs with precise dimensions and consistent quality.

In summary, Precision Sheet Metal Fabrication Laser Cutting Bending Parts involve the manufacturing process of producing accurate and intricate sheet metal components. Precision Sheet Metal Fabrication finds applications in electronics, automotive, aerospace, medical, consumer goods, and architectural industries, among others. Its ability to achieve precise dimensions and high-quality finishes makes it a valuable manufacturing method for various applications.

Main Technical specifications

Picture

![]()

Some Common Types of Precision Sheet Metal Fabrication Laser Cutting Bending Parts

1. Brackets: Brackets are used for mounting or supporting other components. They can be customized in various shapes and sizes to fit specific requirements.

2. Enclosures and Panels: Enclosures and panels are protective covers or housing for electronic equipment, control panels, or machinery. They are often fabricated using sheet metal and require precise cutting and bending to accommodate various features and access points.

3. Chassis: Chassis refers to the framework or structure that holds and supports various components within a system or device. Sheet metal fabrication is commonly used to create chassis for electronic devices, computers, appliances, or industrial equipment.

4. Frames and Supports: Frames and supports provide structural integrity and support for various applications. They can be designed and fabricated to withstand specific loads and forces while maintaining dimensional accuracy.

5. Channels and Profiles: Channels and profiles are custom-formed sheet metal parts that have specific shapes and cross-sections. They are commonly used for structural or functional purposes, such as cable management, ventilation, or guiding components within a system.

6. Covers and Plates: Covers and plates are flat or curved sheet metal parts used to protect or enclose other components or systems. They can be designed with specific cutouts, holes, or fastening features to accommodate specific needs.

7. Mounting Hardware: Mounting hardware includes various types of brackets, clips, or fasteners used to secure components or assemblies to other surfaces or structures. These parts often require precise fabrication to ensure proper fit and functionality.

8. Heat Sinks: Heat sinks are components designed to dissipate heat generated by electronic devices or systems. They are commonly fabricated using sheet metal with intricate fin structures to maximize heat transfer efficiency.

9. Decorative Trim and Accents: Sheet metal fabrication can also be used to create decorative trim or accents for applications that require an aesthetic appeal. These parts often involve complex shapes, patterns, or engraving.

These are just a few examples of the common types of Sheet Metal Laser Cutting Bending Fabrication Parts. The versatility of the process allows for the production of a wide range of components tailored to specific needs in various industries.